2277 Longyang Rd. Pudong, Shanghai, China info@mixingchina.com

YLB Forced Intermittent Movable Asphalt Mixing Plant

- Location: Russia

- Model: YLB

- Startup: 2018

- Equipment highlights: Efficient production, energy conservation and environmental protection.

YLB Forced Intermittent Movable Asphalt Mixing Plant

Introduction& Advantages

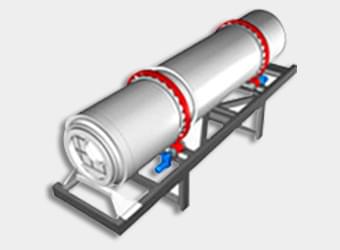

YLB series forced intermittent movable asphalt mixing plant is a new type of asphalt mixing equipment independently developed by NFLG on the basis of LB series modular asphalt mixing equipment, combined with international advanced technology and scientific research achievements. It is convenient to move and transfer, and is the ideal equipment for the production of asphalt mixture for small and medium-sized road construction and maintenance projects.

- Main components with modular design for easy installation, transferring and maintenance.

- The grading is correct, the measurement accuracy is high, it is easy to control, and the quality of the finished material is good.

Parameters

| Model | YLB |

| Rated output | 120t/h |

| Cold bin | 4×10m³ |

| Number of screen layers | 4 layers |

| Capacity of mixer | 1500kg |

| Towing speed | 40km/h |

| Installed power | 374kW |

Drying system

environmental protection and stable operationOptimize the design of the flight structure of the drying drum, heating evenly, and the drum is covered with thermal insulation material and stainless steel overlaying to effectively prevent heat loss, high heat energy utilization rate; long service life of components, stable and reliable operation. And it is 20% energy saving compared to the original drying system.

Dust collection system

intelligent operation guarantees productionStep-rotary reverse jet cleaning, intelligent control of the cleaning frequency, the effective operating area of NOMEX filter bags can be as high as 98%, reaching EU standard emissions (< 20mg/Nm³), realizing the stability of negative pressure in the drum and ensuring the production quality of asphalt mixture.

Vibrate screen system

durable and great performanceThe amplitude matches well with vibrating frequency. The system is strong and durable, great screening effect with the screening accuracy up to 95%.Mesh is easy to change and maintain.

Metering system

secondary metering, stable and reliableThe system uses the weighting mechanism with strong adaptive capability.The system uses the unique patented two doors by coarse and fine feeding for accurate metering.The axial flow asphalt balance uses the unique secondary tracking and metering patent to provide a stable and reliable asphalt-aggregate ratio.

Mixing system

wear-resistant and durable, increase speed and reduce consumptionThe wear-resistant parts imported from Sweden with a long service life. Using simulation to optimize the technology of material movement and stirring speed, the quality control of the HMA is stable, the stirring efficiency is increased by 25%, and the energy consumption is reduced by 20%.

Demand customized

varies with needs to maximize the efficiencyNFLG provides scientific production solution design according to the actual needs of customer projects.